CAPABILITIES

Héroux-Devtek Spain offers complete end-to-end support from conceptual design to qualification, manufacturing and after-sales service throughout the product’s lifecycle.

R&D

For HD Spain the investment in R&D is the key for the sustainable development of the company. That is why, since the very beginning of the company, we are dedicated to developing the main technologies which are essential for the future aeronautical programmes.

DEVELOPMENT ENGINEERING

HD Spain has a wide range of highly qualified personnel with extensive experience, computer-assisted design programmes (CATIA), finite elements analysis (ALGOR, ELFINI), fluid mechanics analysis (FLUENT) and systems dynamic analysis (MATLAB-SIMULINK). In addition to that, we use tools (PLM software ENOVIA) to control the life cycle of the product.

We provide complete and integrated engineering services, with dedicated expert teams working in the different domains coordinated by a Technical Project Leader under the responsibility of a Program Manager who ensures the concurrent engineering phases with the other areas of the company:

- Design: Conceptual / Detail

- Stress Analysis: Static, Dynamic, Fatigue and Damage Tolerance

- Simulation: Modelling / CFD

- Ground testing

- Configuration Control

Based on state-of-the-art management of the requirements from our customers, our team of engineers have a wide experience in developing Hydraulic and Electromechanical Actuation Systems, complete Hydraulic Systems for Aircrafts and Helicopters and Mechanical Systems. Our expertise covers all Aircraft Systems where Actuation is required, from Primary Flight Controls to Cargo Doors through all kind of Landing Gear Actuation (Steering, retraction, Looking), as well as some engine application as Engine Bleed Air, Nozzle and Cowls.

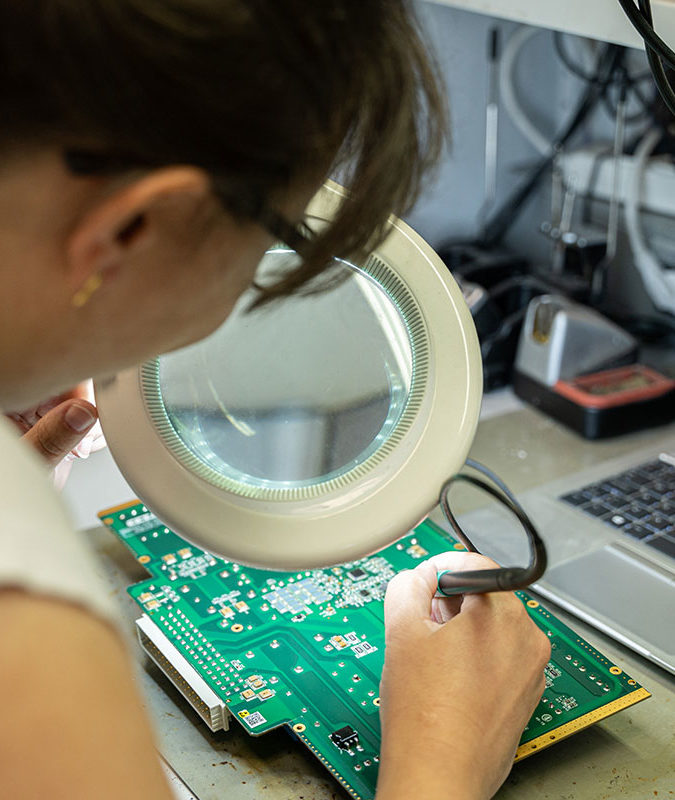

ELECTRONIC DEVELOPMENT ENGINEERING

HD Spain develops hi-tech electronic equipment for managing aircraft actuation systems based on customer specifications, such as electronic control units and power supply units. Our capabilities include the following:

- Electronic engineering team qualified to perform all certification activities according to RTCA/DO-254 and RTCA/DO-178B/C for all DAL categories.

- Full development cycle, including all phases of the design, from customer specification to final verification

- Electronic laboratory equipped with all needed tools to perform the validation, verification and integration of the prototypes, and acceptance tests to our production equipment.

- Testing techniques, including different in-the-loop strategies, HALT/HASS and reliability growth techniques

- Full capability for digital twin approach: simulation models, prototype testing, model-prototype data results correlation

Moreover, we provide extensive support to our customers along the life cycle of the product, from series production tests to failure troubleshooting and repair for in-service equipment.

RMTS ENGINEERING

In order to provide a complete Development Engineering solution, we perform RMTS Engineering activities to ensure a suitable product support to our system and equipment along the complete product life cycle.

- Reliability analysis: Reliability predictions (MTBF) calculated from in-service data of similar equipment, NPRD-11, NPRD-16, MIL-HDBK-217F, FIDES. Development of HALT/ALT and reliability growth techniques.

- Safety process within the frame of the MIL-STD-882 or SAE-ARP4761: From Preliminary System Safety Assessment (PSSA), performing FMEA, FMES, CMA, FTA, to System Safety Assessment (SSA). Development Assurance Process as per SAE-ARP4754, analysing DAL system level, assignation of IDAL level to the equipment.

- Maintainability activities: Maintainability analysis to define the maintenance concept at all levels, implementing predictive maintenance whenever is possible, or defining preventive maintenance when necessary due to safety concerns (following MSG-3 guideline)

- Testability analyses. Built-In Test (PBIT, CBIT & IBIT) to enhance the health monitoring (HM) and maintainability. Capability on HD Spain to develop on site Electronic Control Unit comprising HM and failures detection/isolation.

The RMTS Engineering activities during development phase are performed to ensure a suitable product support to our system and equipment along the complete product life cycle.

QUALIFICATION TEST

We have a state-of-the-art qualification test laboratory where we perform qualification tests on all the equipment we design. Our team of test engineers and operators define development and complex qualification tests procedures for each program in accordance with the requirements of the customers and the nature of the project.

Our advanced aerospace testing capabilities have allowed to conduct environmental and electrical tests as per MIL-STD-810/DO-160 standards and also, performance, structural strength, hydraulic and mechanical fatigue, and endurance tests. We also count on a dedicated assembly area for the production of the Ground and Flight Test Units, including specific instrumentation, and the initial production units.

Our team of experts have at their disposition general purpose hydraulic and electromechanical test benches and specifically developed dedicated test rigs for complex systems simulating aircraft environment (kinematics, loads and pressures, working at different fluid and ambient temperatures). They also have on-site tools to perform vibration and preliminary EMI/EMC testing.

We can also perform tests at our partners test laboratories when necessary.

MANUFACTURING

HD Spain’s excellent perfomance in terms of quality, schedule and cost, is based on the integration of manufacturing engineering,manufacturing (internal and external) and Production Control.

Our inventory machinery, includes high quality surface finishing equipment, CNC-Turning-Boring-Milling Centre, with counter spindle, bottom slide and control Sinumerik, an automation of deburring process, and a machine predictive monitoring.

In addition, HD Spain has a Special Processes area (Heat Treatment and Surface Treatments) which include the installation and certification (NADCAP) of capabilities like HVOF, CAD and chrome.

HD Spain works in accordance with a quality management system that includes quality and environmental management pursuant to the most widespread international standards observed in our sector.

HD Spain has advanced NDT processes using innovation technology to inspect and analyse anomalies with specialized applications speeding up the inspection process with accurate results without interrupting our workflow.

ASSEMBLY

Assembly & Testing Areas are organized in specialized modules, equipped with the latest technologies which drive our work efficiency. We use fully automated benches and intelligent assembly modules.

We have test benches to test all equipment that we manufacture, from load beams, pneumatic test benches, testing fuels to hydraulic test benches with the ability to perform PATs with different hydraulic fluids. (MIL-PRF-5606, MIL-PRF-83282, MIL-PRF-87257, MIL-PRF-23699, Skydrol LD 4/LD5, HYJET TYPE IV/V, MIL-PRF-87252, DOWCOL-10, MIL-L-23699, among others…).In addition to this, we have implemented the most innovated systems of handling called “Zero Gravity Pneumatic Manipulator” and digital technologies to support our processes linked to Industry 4.0.

According to our LEAN philosophy, we have put in place standardized and robust processes with specific fixtures & tools. Trained personnel and skilled workforce guarantee the quality and best lead time response certifying that the equipment leaves the factory operational and ready to be fitted in the aircraft.

MRO & SERVICES

Mechanical, Pneumatical, Hydraulic components, Landing Gears, fuel systems, EMA’s, Electronic Control Units, electric generators and cooling / air conditioning equipment, offering flexible Maintenance solutions for OEM and Non-OEM components.